An Unbiased View of Premier Aluminum Llc

The Ultimate Guide To Premier Aluminum Llc

Table of ContentsPremier Aluminum Llc - QuestionsExamine This Report about Premier Aluminum LlcFascination About Premier Aluminum LlcThe Best Strategy To Use For Premier Aluminum LlcThe smart Trick of Premier Aluminum Llc That Nobody is Talking About

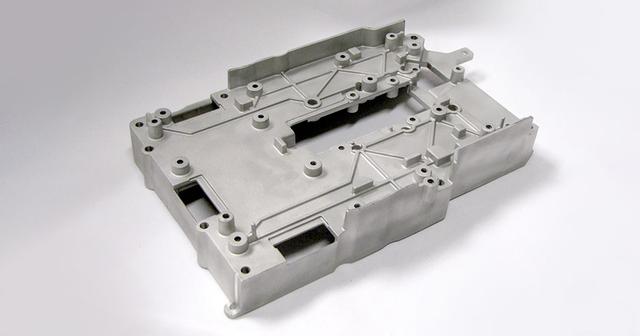

When choosing a light weight aluminum shop for your manufacturing needs, it's vital to research several elements. One of the most essential aspects to take into consideration is the experience and proficiency of the shop. Choosing a factory that has the best expertise of the light weight aluminum casting process, and the portfolio to reveal for it, helps to have an effective outcome for your project.Having the experience and sector knowledge to craft your spreadings for optimum production and high quality outcomes will certainly streamline the job. Making light weight aluminum spreading calls for a facility collection of processes to attain the ideal results. When picking a brand-new light weight aluminum shop to partner with, ensure they have considerable industry experience and are experienced regarding all facets of the aluminum casting procedure: style, manufacturing, product analysis, and product screening.

The shop should likewise have a proven track document of providing exceptional items that satisfy or surpass customer expectations. Quality assurance ought to additionally be at the top of your list when selecting an aluminum foundry. By dealing with a qualified factory that follows the criteria for quality assurance, you can shield the integrity of your product and ensure it meets your specs.

The Only Guide to Premier Aluminum Llc

This specific process can be automated and duplicated. Various elements that extremely made complex shapes can be manufactured utilizing this process. Consequently, huge volumes of components can be generated in simply a brief period of time. Before you begin looking for a reputable light weight aluminum pass away caster, there are some vital points that you need to do first.

You need to ask yourself what kind of light weight aluminum die castings you call for. After establishing what you call for, you need to state the specifications of the aluminum pass away castings you require. Identify the weight, density, dimension, and various other specifications of the light weight aluminum die-cast you call for. It would certainly likewise be better if you can attract and reveal all the measurements of the light weight aluminum die-cast.

Do you know just how much cash you have to invest in the products? In order to do this, the most effective point to do is to determine the number of light weight aluminum diecasts you require. After having this information, you can start researching aluminum die-casting producers. You can do this by simply typing the key phrase" Light weight aluminum pass away casting suppliers" on the Google online search engine.

Some of the concerns you require to ask on your own are whether they have experienced and well-trained operators, the length of time their company has been in operation, or if they have some accomplishments. You can frequently get the response to these concerns from the producer's internet site. You can investigate various other internet sites or outside resources to verify if the info provided on the supplier's site is authentic.

How Premier Aluminum Llc can Save You Time, Stress, and Money.

One more point you need to take into consideration is the producer's capability to produce aluminum die-casting items. To put it simply, the quantity of items the manufacturer can generate at a given time. Some of the crucial questions you need to ask yourself are whether the producer can produce a greater quantity or can the maker satisfy your demands.

(https://www.pearltrees.com/premieraluminum#item698292618)What happens if your firm calls for 10,000 pieces of certain machine components from the manufacturer within one month? You purchased this quantity; however, the manufacturer can only produce 5000 pieces of these machine components within one month (Aluminum Casting). Consequently, you won't have the ability to obtain the amount that you order promptly

The Definitive Guide to Premier Aluminum Llc

It is crucial that you need to ask if the manufacturer is implementing an internal tooling process. Additionally, you have to ask the supplier exactly how a lot the price of internal tooling is. Maintain in mind that the internal tooling process, which allows you to produce distinct layouts and forms can be an added price.

This aspect directly correlates with the maker's manufacturing ability. Foundries in Wisconsin. You have to look for a maker that can ensure quicker shipment of items.

This suggests that there are a number of alternatives that you can choose from. That is why it is substantially suggested that you need to choose a producer that can create various types of light weight aluminum die-cast items.

Getting My Premier Aluminum Llc To Work

A lot of often, my website these aluminum die-casting items will call for some styles, machining, or ending up touches. Having this in mind, you should try to find a maker that can execute a range of additional finishing works once pass away spreading is done. Some examples of completing operations include Chromating, CNC Machining, Sandblasting, Powder finishing, Anodized, E-coating, Damp paint, Plating, and a lot more.

Die casting is one of the most cost-effective, accurate, and protean production processes in the world moment. The process entails suitable molten significance, under pressure, into a suitable die (planet), and formerly solidified it can be ejected and completed (if required) in a selection of methods.